Based on its many years of experience in valve construction, Südmo offers a comprehensive, refined double-seat valve for implementation and automation of widely varying production processes in the food and beverage industry.

Why use Südmo double seat valves?

As well as a wide range, the series is characterized by ease of handling and maintenance, and is therefore the ideal component for operating your processes with maximum efficiency and safely.

•Reliable separation of two media [e.g.product and cleaning liquid]

>Two sealing elements work separately

>Leakage chamber open to atmosphere

- Avoids pressure build-up

- Visual leak detection

•All surfaces in contact with product can br cleaned

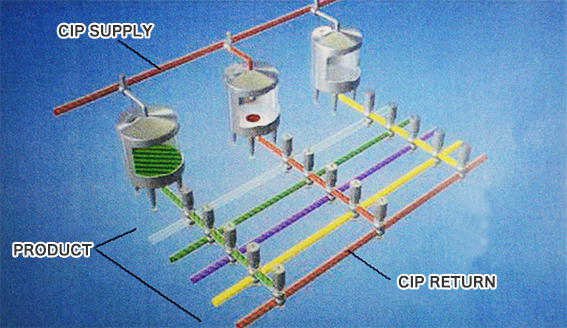

The function of the double-seat valves is shown in the below tank farm application example.

Simultaneous, programmed filling,emptying and cleaning of four production lines without risk of mixing.Reliable separation of upper and lower valve housing allows one or more lines or tanks [purple and red lines] to be cleaned during production [yellow and green lines].

In seat area

In shaft area